In 1998, our company was contacted by Eaton Aeroquip, with the intent of acquiring an estimate for some autoclaves they would need for expanding an existing facility’s industrial rubber hose production.

Design Scope

Aeroquip’s original intent was to design the facility’s autoclave equipment in-house, based on the existing facility’s autoclave designs. The current facility’s rubber hose manufacturing process required several days and up to 50 employees to manufacture the hoses cured inside the facility’s existing autoclaves.

Once the specifications were created, Aeroquip would award contracts to vendors to construct autoclaves and have another contractor design, construct and install the autoclave’s piping and automation systems in along with the autoclaves.

We met with Aeroquip’s key stakeholders for the project and defined what their current pain points were for the production of the hose using the current autoclave designs. A major point was producing critical orders of hose for clients in a timely manner. This sometimes required a particular amount of hose to be manufactured and ready for shipment to a client within a 48 hour period.

Through several meetings with the stakeholders, we designed a new autoclave system that would allow them to meet those critical order timelines. We were given not only the contract to manufacture the autoclaves, but also for the design, construction, and installation of all the equipment Aeroquip would need to operate the autoclaves. The scope of the contract included:

- Design, construction, and installation of two new autoclaves.

- Design, construction, and installation of the autoclaves piping and valve systems;

- Design, construction, and installation of the autoclaves automation system;

- Design, construction, and installation of the autoclaves material handling system

Process

Aeroquip’s new autoclave system would become known as the pan cell system. The pan cell included the equipment needed to manufacture the industrial rubber hose. This included the extruders, braiders, liners, pan loaders, vulcanizers, hose testers, and hose packaging.

|

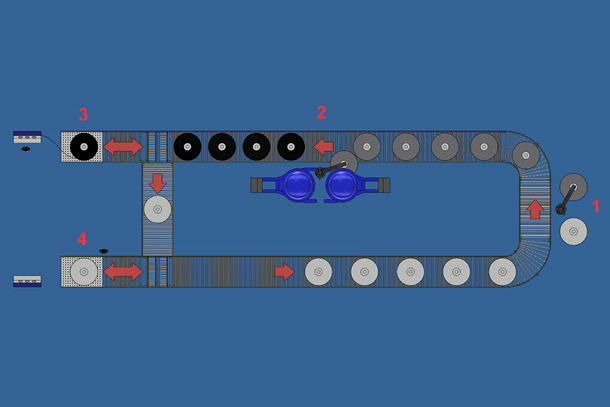

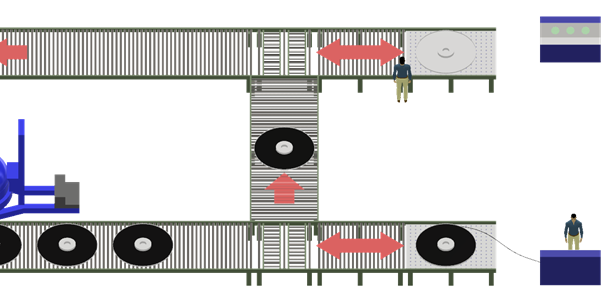

| Fig. 1- New autoclaves material handling system |

Figure 1 shows the new autoclaves with their associated material handling system. The system includes:

1: Pan loading station, which includes pan transfer arm 01

2: Autoclave Load/Unload Station, which includes pan transfer arm 02

3 & 4: Pan Unload/HoseTesting/Hose Packing stations

|

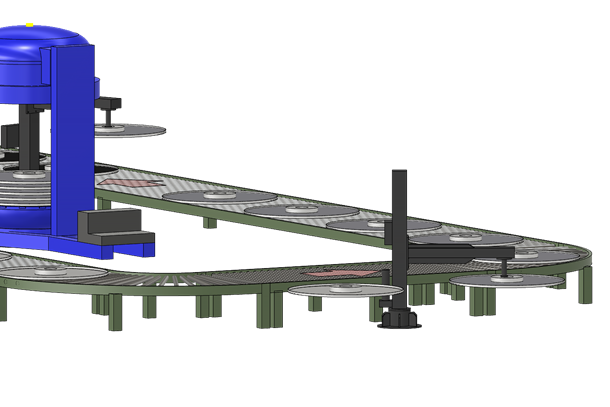

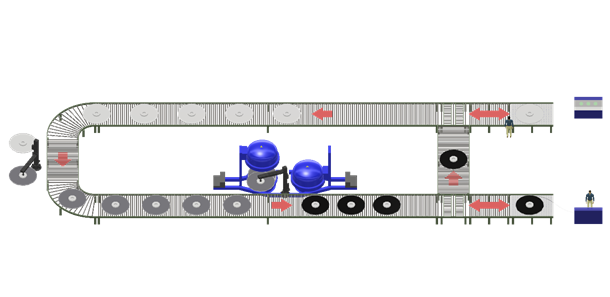

| Fig. 2- Pan Loading Station |

The pan loading station, as shown in figure 2, receives the uncured hose after it has been coiled into the pan by the pan cell’s pan loading machine. The pan is then automatically moved by pan transfer arm 01 onto the material handling system’s conveyor. The arm then signals the conveyor to move the uncured hose pan out of the way and move an empty pan into position. Once the empty pan is in position, the arm removes the pan from the conveyor onto the pan loading machine so the pan can be loaded with the uncured hose.

|

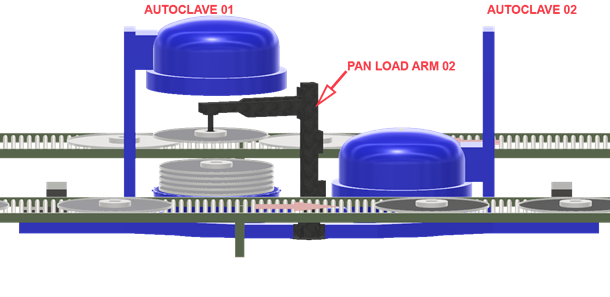

| Fig. 3- Autoclave Load/Unload Station |

After the pan of the uncured hose is loaded onto the conveyor, pan transfer arm 02 takes over. This arm signals when a pan of the uncured hose is needed. The conveyor moves a pan into position. The arm then removes the pan from the conveyor and stacks it into one of the autoclaves awaiting a load of the uncured hose. Once the arm has filled the autoclave with the proper number of pans, the autoclave closes and begins its cure cycle. While this cycle is processing, the arm begins unloading the opposite autoclave that completed its cure cycle. The arm signals the autoclave to open, removes each pan of cured hose from the autoclave, and places it onto the conveyor. Once a pan is set in place, the arm signals the conveyor to move the pan to the cured hose staging area.

|

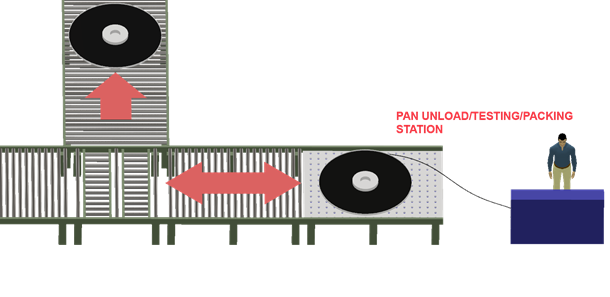

| Fig 4- Pan Unload/HoseTesting/Hose Packing station |

This project’s material handling system included two of the pan unload/testing/packing stations as shown in Figure 4. This is the only time an employee is involved in the material handling phase of the hose. When an employee is ready to unload and test the hose, a button is pressed at the testing station. The conveyor then moves a pan of the cured hose into the test station. Here the inner mandrel is removed from the cured hose. The hose is then tested for compliance with the manufacturer’s specifications. Once tested, the hose is uncoiled from the pan and loaded into its packing container for shipment.

|

| Fig. 5- Pan unload/testing station calling for new pan of cured hose |

Finally, the employee presses another button to signal the conveyor it’s ready for another pan of the cured hose. The conveyor removes the pan from the testing station and moves a new pan of the cured hose into the station.

|

| Fig. 6- Empty pans waiting to be re-loaded |

The conveyor moves the empty pans into the staging area where they wait for pan transfer arm 01 to call for them to be re-loaded with the uncured hose.

Results

This pan cell system has been in operation for over 21 years now and is still producing cured hose for the client. The main pain point was eliminated with this system. Aeroquip, now known as Eaton, can meet the production time for critical orders in less than 24 hours. An additional benefit of this system is the decrease in labor needed to produce the cured hose from 50 employees to just nine.

This includes the employees needed to produce the hose’s inner mandrel, extrude the hose inner cover, braid the hose, produce the hose’s outer cover, line print the hose, cure the hose, remove the inner mandrel, test the hose, and pack the hose for shipment.

Could your facility use a new autoclave system? Tank Fab, Inc. is your one-stop-shop for all of your autoclave needs. We are more than just autoclaves. We also provide you with everything that makes your autoclave work. Contact us today, and let us help you fill your autoclave needs.

Tank Fab Inc, 8787 Hwy 117 S, Rocky Point, NC 28457-6001

P- 910-675-8999