One of the most important aspects of autoclave maintenance is the door.

It’s designed to open quickly, be safe and reliable.

But if the proper precautions aren’t followed, damage to the autoclave and whatever is around it – including people – can occur.

This can slow production and cause lags that will cost you revenue in the long run.

Avoid injury by understanding the design and operation of the mechanism and any special characteristics of how it operates.

It’s important to remember that the door mechanism is very heavy and must be moved with care and caution. Gradual and gentle movements will keep the door from hitting other components and causing damage.

Here’s what you need to know about the proper way to open and close your autoclave’s door.

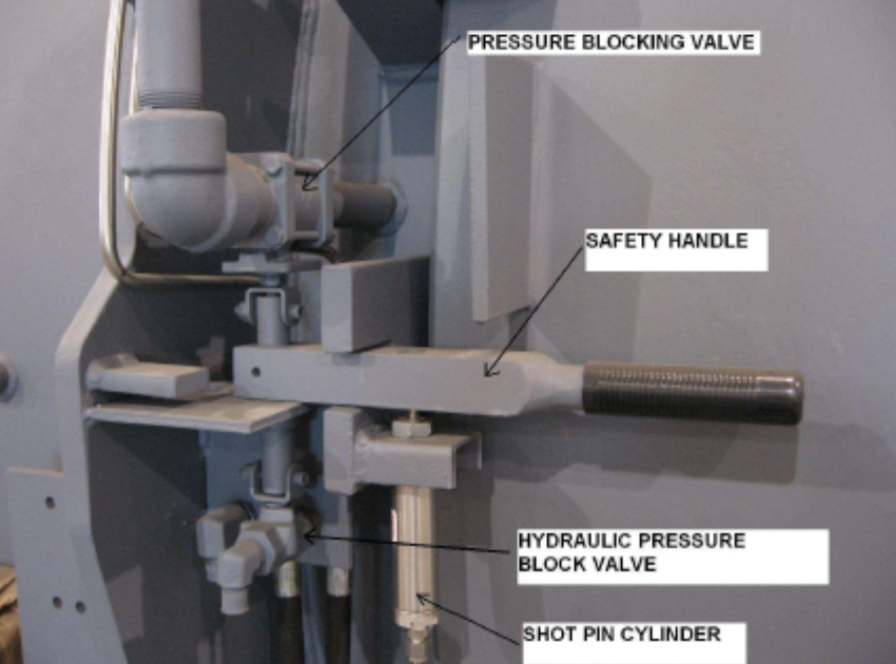

This mechanism prevents the operator from inadvertently opening the door while the autoclave is under pressure. It can also disable the process inside the vessel.

Each autoclave door is equipped with a door safety interlock.

It has two main purposes:

A door safety interlock mechanism is well-tested before it’s used in autoclave construction.

Warning: Under no circumstances should you modify, alter or circumvent this important safety device.

A pressure-operated spring pins the operating handle in the locked position anytime there is pressure in the vessel.

When the door safety interlock handle is used, the vessel pressure indicator valve is activated.

This valve is to be a visual, audible indicator to alert the operator if there’s any pressure remaining in the vessel when the door safety interlock handle is opened.

Warning: If the vessel pressure indicator valve shows that ANY pressure is left in the vessel, do NOT open the door. There is still dangerous pressure in the autoclave.

WARNING! Not all doors are designed and/or operated in the same manner. These procedures are for informational purposes only! Use the procedures provided with your autoclave for proper operation and safety!

Warning: Never let the door to come to a sudden stop when it’s traveling at full speed. The weight of the door could damage the hydraulic system if allowed to stop abruptly.

Don’t keep pushing the door further once it’s in the open position. This may damage the door’s hinge.

For your safety and the safety of those around you, it’s important for you to follow the correct procedures for closing the autoclave’s door, as well.

Warning: Don’t let the door head slam closed. Damage may result.

Don’t continue to push the door closed once it’s in the fully-closed position. This may damage the door’s hinge. The locking ring’s job is to secure the door and fully seal it.

You want to get the most out of your pressure vessel.

When you follow the correct autoclave maintenance and safety guidelines, you won’t have to worry about production lags and lost revenue.

Knowing how to properly open and close your autoclave’s door will prevent injury and protect your investment.