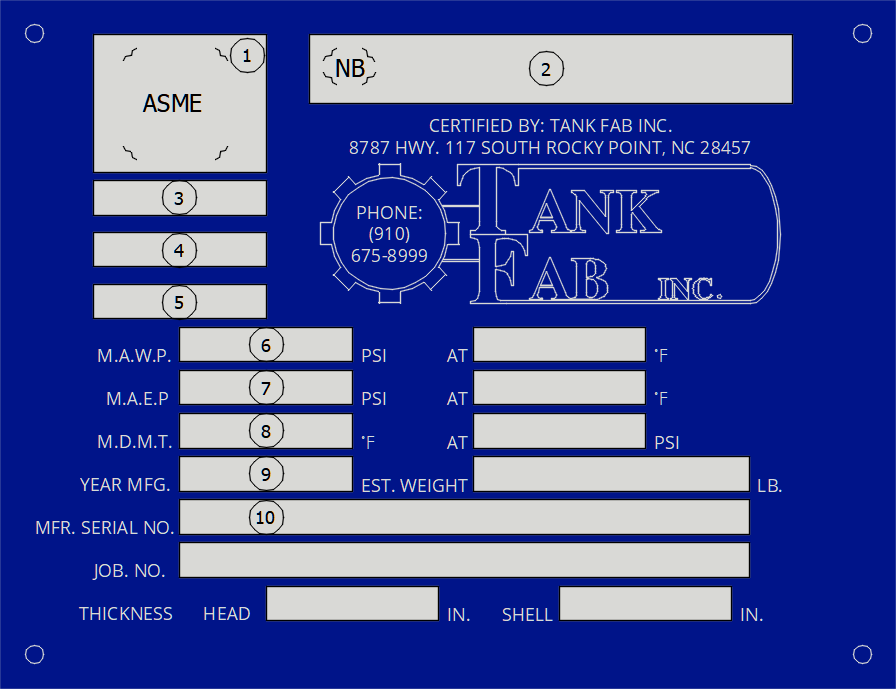

Every new pressure vessel includes a nameplate.

The nameplate is one of the most important parts of your pressure vessel. Without it, the operation of your vessel may be in direct violation of federal, state, and/or local laws or regulations.

Let’s take a closer look at the pressure vessel nameplate and why it’s so important. (Note: The numbers on our list correspond to the numbers in the picture below.)

ASME Code nameplate sample

ASME Code nameplate sample

All pressure vessels we build are manufactured in accordance with the ASME Code.

According to this standard, the vessel must be built with a nameplate. Once the pressure vessel passes its final inspection, the ASME Code mark is stamped onto the nameplate, proving the vessel was built in accordance with this standard.

This location on your pressure vessel nameplate is reserved for the display of its National Board number. If the pressure vessel manufacturer chooses to register the vessel’s manufacturer’s data report with the National Board, a unique number is assigned to the pressure vessel and is displayed here.

This is a great benefit to you, as the pressure vessel owner. The document, along with the nameplate, is proof to all federal, state, and local regulators that your pressure vessel meets the requirements of the ASME Code.

Without the data report and the nameplate, most inspectors will not allow the operation of the pressure vessel within their jurisdiction. If you ever lose this document, you can contact the National Board, and, for a small fee, receive a copy of the manufacturer’s data report.

You’ll need the following information off of the nameplate when placing an order for this report:

Note that registering the pressure vessel with the National Board is not a requirement. We feel this is an invaluable benefit for all of our clients, so we register all of the pressure vessels we manufacture.

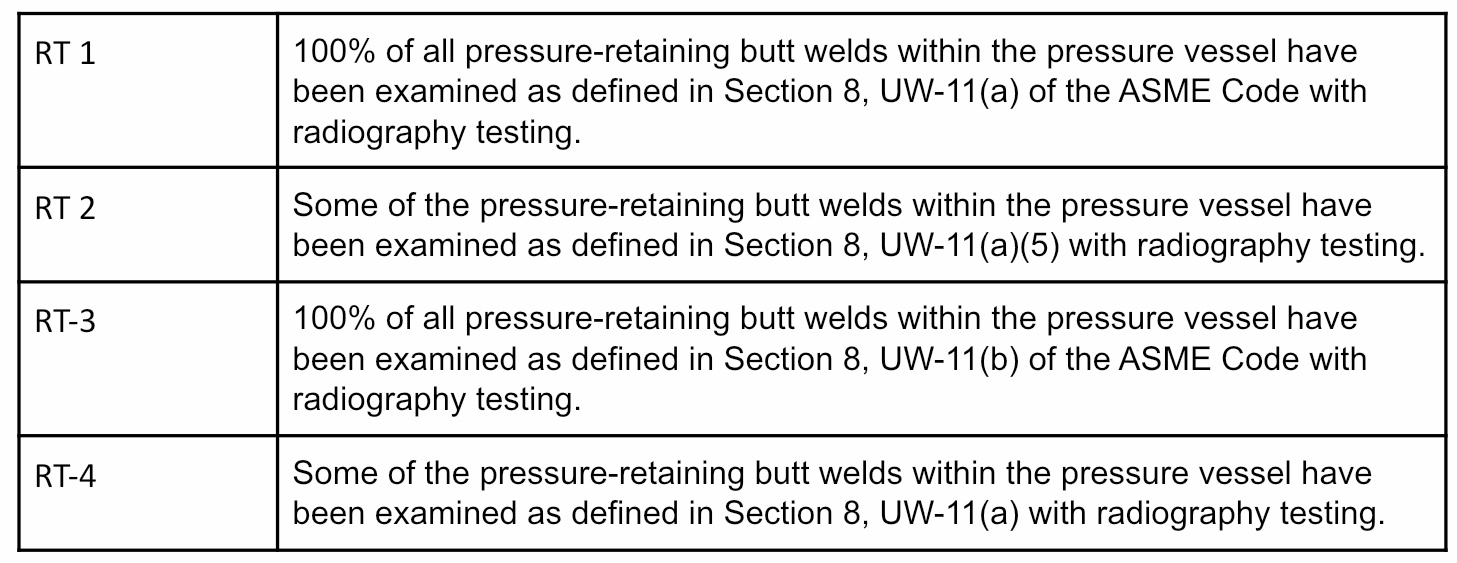

This area of the pressure vessel nameplate is reserved for the identifier of the type of construction that was used to manufacture your pressure vessel. Below is a list of the different identifiers that may be used.

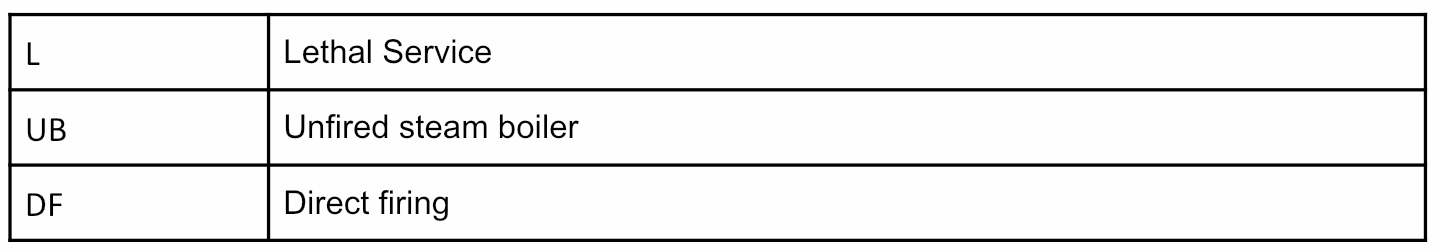

If your pressure vessel is manufactured for special service use, as defined within the ASME Code, then an identifier is also displayed in this area of the nameplate. This identifier follows the identifiers listed above, preceded by a hyphen. The identifiers for the different special services are shown below.

For example, if your pressure vessel was manufactured with welded construction and for lethal service, the identifier would be displayed as “W-L”.

During the manufacturing phase of your pressure vessel, it may have had an examination of its welds with radiography testing. If so, one of the following identifiers will be displayed in this area of the nameplate.

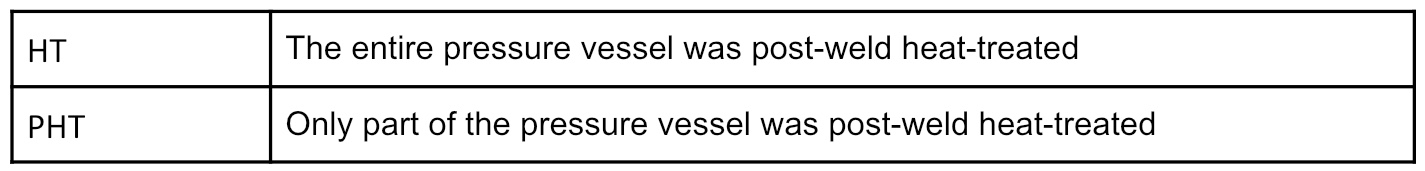

Your pressure vessel may have been post-weld heat-treated during its manufacturing phase of construction.

If so, one of the following identifiers will be displayed in this area of the pressure vessel nameplate.

In this area of the nameplate you’ll find the pressure vessel’s maximum allowable working pressure and the maximum temperature.

Note that if you plan to use the pressure vessel at this pressure above the maximum temperature displayed here, it could lead to a catastrophic failure of the vessel.

It’s also important to know that this pressure is not the pressure you will work the pressure vessel at during normal operations. (See the terms “Design Pressure” and “Maximum Allowable Working Pressure” in our You Need to Know These 21 Pressure Vessel Manufacturing Terms blog post.)

Here’s where you’ll find the pressure vessel’s maximum allowable external pressure (vacuum) and the maximum temperature.

Note that if you plan to use the pressure vessel at this pressure above the temperature displayed here, you could experience a catastrophic failure of your pressure vessel.

The minimum temperature that the pressure vessel was designed to operate at is displayed here. Operating the pressure vessel below this temperature could also lead to a disastrous situation.

If you intend to use the pressure vessel outside of the figures listed in areas 6, 7, or 8 as defined in this post, it is highly recommended you consult with an engineer that has experience with the ASME Code.

If not, what might happen? You got it – failure. And not only of the equipment, but it could also create a potentially fatal scenario for your employees or anyone in the immediate vicinity.

This is the year your pressure vessel was manufactured. This piece of information is particularly important if you are purchasing a used pressure vessel for use in your facility.

The ASME Code requirements have changed in many ways in the past 20 years. Buying a used pressure vessel that was built more than 20 years ago may not meet today’s regulations in your state or local jurisdiction.

ALWAYS research what those requirements are prior to buying a used pressure vessel. Doing so will save you money and the headaches of disposing of a multiple ton paperweight because it doesn’t meet today’s regulations.

Every pressure vessel a manufacturer builds following the ASME Code must be provided with a unique serial number. This is where that serial number is displayed.

The item numbers 1 through 10 shown in figure 1 are required by the ASME Code to be displayed on a pressure vessel nameplate.

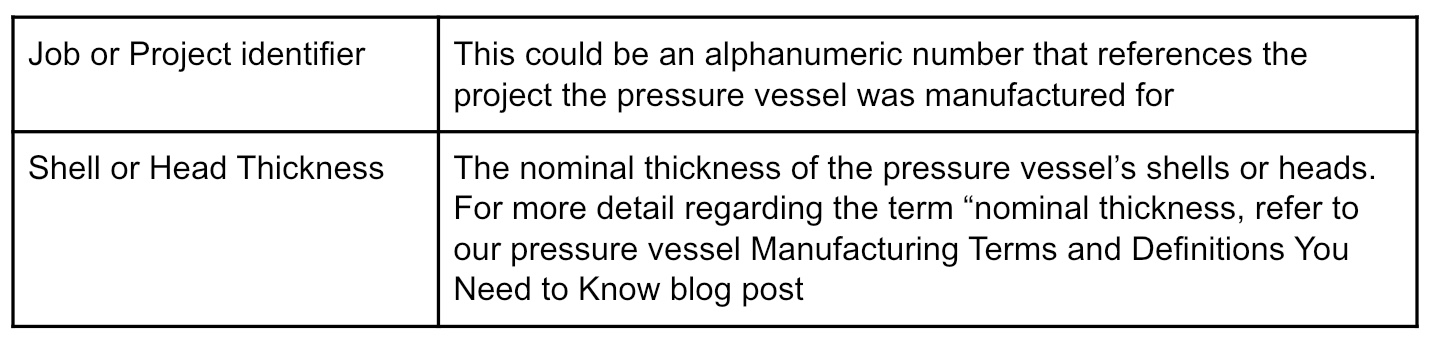

However, additional information can be provided as a convenience for you. Some examples of these are:

Now that you understand what the information means on the nameplate, where is the nameplate located at? Unfortunately, the ASME Code does not specifically specify the location for a pressure vessel’s nameplate.

Here are a couple of places to look:

Now that you have a better understanding of all the different elements of your pressure vessel’s nameplate, you should be able to see why it is one of the most important parts of your pressure vessel’s assembly.

You need to be confident that your pressure vessel meets federal, state, and local regulations so that nothing causes your production to slow down.