The type of pressure-treated wood you use matters because the amount of preservative varies by the use. Also, the wrong kind in the wrong environment can cause the wood to deteriorate more quickly.

You’re ready to tackle a building project.

The problem is understanding what type of pressure-treated wood you should use?

You want whatever you’re building to remain useful and look great for a long time – without issues.

To do that, you have to understand what type of wood to use because there’s a LOT to choose from.

Here’s help finding the right pressure-treated wood for your next project.

In today’s world, not all pressure-treated wood products are created equal. Depending on the project you’re building, choosing the right materials for your project will determine if it provides you many years of enjoyment or a few years of headaches.

If you think all pressure-treated wood products at the big box store or local building supply are the same, think again.

And unfortunately, based on my personal experience, many of the associates that work at the larger big box stores are not very knowledgeable about which pressure-treated wood products you should use for your project.

Pressure-treated wood products are preserved by wood treating facilities based on the American Wood Protection Association standards.

These standards detail what type and how much wood preservative will be used to preserve the pressure-treated wood products based on how the wood will be used. For example, wood pickets, rails, or panels used for wood fencing are pressure treated differently than the wood posts placed in the ground to support the fence.

So, how do you know which type of wood product to choose for your project?

Fortunately for us, the Western Wood Preservers Institute (WWPI) and the American Wood Protection Association (AWPA) have created a free downloadable specification sheet and infographic you can use to educate yourself on which preserved wood product you will need for your project. You can download it here:

Great! You’ve downloaded the infographic, and know which pressure-treated wood product you need to get.

But how do you know you’re getting the right one at the store?

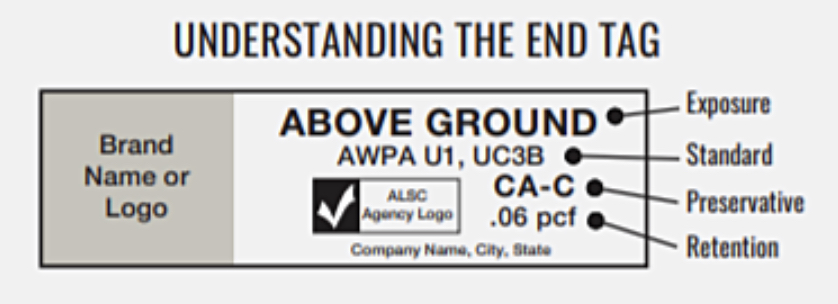

You’ll use the little tag attached to the pressure-treated wood product. Here’s an example.

The tag has a variety of pieces of information on it, but the two you need to understand are the Exposure and Standard.

The tag has a variety of pieces of information on it, but the two you need to understand are the Exposure and Standard.

The exposure part of the tag will let you know if wood products can be used in the ground or not.

If the label is printed “Above Ground,” this product should not be used if it is going to be in contact with the ground. Doing so will cause the wood to deteriorate and fail in a short period of time.

If the label is printed, “Ground Contact,” then you can use the wood product for ground contact or in-ground use.

Easy right?

Well, not exactly.

There are different types of above ground and ground contact categories within the AWPA standards. The categories determine what type and how much wood preservative is used to treat the wood product based on the application it is going to be used for. This is where the Standard part of the tag comes in.

The standard part of the tag will list the AWPA’s Use Category Code, also known as the UC Code in the wood treating industry.

This code will tell you what you can use this wood product for.

Listed below are the codes you will need to know for the more common do-it-yourself projects.

This wood product is to be used for interior construction in dry locations. It should not be used if the wood product is going to be in contact with the ground, foundations, or may possibly become damp from weather and interior sources of water such as leaking plumbing, condensation, pools, and spas.

Examples: Interior furniture, construction furnishings, or millwork.

This wood product is to be used for interior construction in damp locations. However, it shouldn’t be used in interior locations where the wood would be in contact with the ground. The wood product should be protected from the weather but may occasionally be exposed to moisture.

Examples: Interior beams, timbers, flooring, framing, millwork, and sill plates.

This wood product should be used for above ground exterior construction that is either:

Examples: Painted millwork, painted building siding and trim, and painted porch flooring.

Examples: Framing and sheathing, not covered by a weather-resistive barrier, but protected from exposure to liquid water.

This wood product should be used for above ground exterior construction that does not come into contact with the ground.

Examples: Deck flooring, deck rails, stair treads, building roofing such as shakes or shingles, fence pickets or panels.

This wood product should be used for:

Examples: Fence posts, structural support posts such as porch roof posts, stair stringers, landscape walls, deck support posts, deck joist or beams, permanent wood foundations, garden or planter boxes.

This wood product should be used for ground contact in severe environments such as horticultural sites or in areas with a high potential for deterioration or insect damage, or where the wood may be splashed with salt or brackish water.

Examples: Agricultural posts or poles, pier floor decking, building poles, or utility poles.

The next set of categories is broken down based on the geographical location of where the wood product is going to be used.

This wood product should be used for wood exposed to salt and brackish water which includes Long Island, New York, and northward on the east coast of the United States and north of San Francisco, California on the west coast of the United States to the extent that the marine borers can attack them.

Examples: Pier pilings and bracing, bulkheads, or other wood construction that is exposed to brackish or saltwater.

This wood product should be used for wood exposed to salt and brackish water south of Long Island, New York to the southern border of Georgia on the east coast of the United States, and south of San Francisco, California on the west coast of the United States to the extent that the marine borers can attack them.

Examples: Pier pilings and bracing, bulkheads, or other wood construction that is exposed to brackish or saltwater.

This wood product should be used for wood exposed to salt and brackish water south of the state of Georgia in the United States, along the Gulf Coast of the United States, in Hawaii and Puerto Rico, to the extent that the marine borers can attack them.

Examples: Pier pilings and bracing, bulkheads, or other wood construction that is exposed to brackish or saltwater.

WOW! There are a lot of choices!

The new wood preservatives that replaced CCA when it was banned from residential use costs much more to manufacture and use as a wood preservative.

To minimize the cost of these pressure-treated wood products, these categories were revised to minimize the amount of preservative used in various wood products.

There’s one more important factor to note. Notice the wording on the infographic, “Use Category… or higher?”

This is to inform you that it is acceptable to use a higher category wood product if the one listed is not available.

For example, the majority of decking materials used in the United States will be preserved under category number UC3B. Even though you could use wood decking preserved under category UC3A for your covered porch, you’ll most commonly find UC3B decking in the big box and building supply stores.

Choosing the right kind of pressure-treated wood for your building project can be confusing.

This detailed guide should help clear up the muddy water for you when it comes to understanding which preserved wood product to choose the next time you need to tackle a build.