In the manufacturing world, techniques have changed significantly over the years.

After years of working with a variety of industries, we’ve learned the terms that are used most commonly in each and turned them into a list.

Use it to build your vocabulary – and understanding – of manufacturing terms.

Bonus: Since manufacturing is a global business, learning these concepts will be applicable anywhere.

Here are some manufacturing terms and definitions that you need to know.

ASME stands for the American Society of Mechanical Engineers. This is the governing body that manages the standards to which various products are manufactured.

An autoclave is designed, manufactured, and tested according to the ASME Boiler and Pressure Code.

A standard set by the American Society of Mechanical Engineers that regulates the design and construction of boilers and pressure vessels. Within this code, the autoclave is considered a pressure vessel with a door on the end.

Section VIII of the code sets the primary standard for autoclaves.

It’s written by volunteer expert engineers and is regularly reviewed and updated.

Tank Fab manufactures pressure vessels that use steam, pressure and varying exposure times to vulcanize rubber, treat wood, and create fiber cement and aerated concrete. They’re equipped with a quick-opening (aka door) at one end.

Items such as wood or untreated rubber are placed inside the autoclave and subjected to high amounts of pressure and/or vacuum. The result is that the items are now “treated.”

A control system that automatically performs a process or system with minimal or reduced human interaction.

In our case, our EASY Treat™ system automates the process happening inside the autoclave.

Autoclaves or parts of autoclaves that are susceptible to thinning by corrosion, erosion, or mechanical abrasion must be made with greater thickness in those areas to add extra protection.

If no corrosion allowance is added to the design of the autoclave, you’ll have to reduce the working pressure of the autoclave once the material thickness is lower than the autoclave’s design thickness.

Also referred to as “working pressure,” design pressure is the target internal pressure that the autoclave will work at while performing its process.

Note that Maximum Allowable Working Pressure is not the same as design (working) pressure.

Door swing is the radius distance between the autoclave’s inner door face and the outer edge of the door when it is open.

The inner diameter is also called the “ID” and it represents the distance from the inside diameter of the autoclave’s shell and or head.

Outer Diameter – or “OD” – is a measurement of the autoclave’s inner diameter plus the nominal thickness of the autoclave’s shell, times two.

Outer Diameter (OD) = Inner Diameter(ID) +(shell nominal thickness x 2)

Joint efficiency is used when planning for the minimum thickness of the autoclave shell in accordance with the ASME Code.

The ASME requirements assume that a welded joint is more delicate than the material it is fusing together because of porosity, slag inclusion, etc within the seal itself.

Subject to how the weld joint is going to be examined via radiography, a proportion factor is used in the computations for determining the shell and or head thicknesses.

PV Engineering has a great post that goes into more detail about this.

There are different loadings you need to consider when designing an autoclave. The ASME Code lists some of those as:

To go into more detail about this, take a look at UG-22 in section 8 of the ASME Code.

The document that your autoclave manufacturer created after the autoclave was manufactured and tested in accordance with the ASME Code is the manufacturer data report.

The report includes information concerning the design and manufacture of your autoclave.

Here’s some of the information on a typical report:

Here is an example of a manufacturer’s data report. It’s very important that you retain this document for future repairs or alterations you may need to make to your autoclave in the future.

Without it, you will have a very difficult time getting this kind of work approved by your state’s autoclave governing body.

If you don’t have a copy of this document, you may be able to obtain one. The process for doing so is somewhat lengthy, so I’ll write about the process in a future post.

Maximum Allowable Working Pressure, also known as “MAWP,” is the greatest pressure possible within the autoclave, in normal operating conditions.

This is different from the autoclave’s Design Pressure. According to the ASME Code, each autoclave must be designed with some type of pressure-relieving device.

In most cases, this is a pressure relief valve. The pressure relief valve is designed to begin opening at 10% under the autoclave’s MAWP, and fully open at the autoclave’s MAWP. This prevents the autoclave from over-pressurizing which can lead to a dangerous situation.

Maximum Allowable External Pressure, also known as “MAEP,” is the highest amount of external pressure, (vacuum) within the autoclave, in normal operating conditions.

You can find more detail about this in UG-28 in Section 8 of the ASME Code .

The crucial point to remember is to look at the nameplate information on your autoclave. If there is no information on the plate concerning MAEP, external pressure, Maximum Allowable External Pressure, etc., then your autoclave is not designed for external pressure use!

Doing so will most likely cause the autoclave to fail. It would be wise to remember this if you are looking to buy a used autoclave.

Note: Not all autoclaves are made to withstand external pressure – vacuum – use.

The lowest temperature at which your autoclave will work under normal operating conditions is the Minimum Design Metal Temperature.

This number is also listed one the autoclave’s nameplate information. If the autoclave is used at a temperature below the one listed on the nameplate, damage to the autoclave could occur, such as brittle-fracture cracking within the autoclave’s weld joints.

Minimum Thickness measures the depth your autoclave’s shell and heads need to be at to handle the loadings (pressure, internal weight, etc) it has to bear.

Section UG in section 8 of the ASME Code includes the requirements for Minimum Thickness.

The Minimum Thickness of your autoclave’s shells and heads, added to any additional corrosion allowance in the design gives you your Nominal Thickness.

You can find the nominal thickness information for your specific autoclave was on the Manufacturer Data Report.

The Material Handling System is a sub-assembly of your autoclave system.

It consists of the components that are used to move your product into and out of the autoclave.

This includes the carts, tram cars, winches, and tracks the carts and cars move on.

We also design and manufacture these systems. I’m somewhat biased, but I believe this system could increase your autoclave’s output production by more than 50%!

The National Board Number is registered by the autoclave manufacturer with the National Board of Pressure Vessel Inspectors.

When you apply and register this number with the National Board, it allows you, the autoclave owner, to obtain a copy of the Manufacturer Data Report in case yours gets lost.

If your autoclave was registered with the National Board, the autoclave’s nameplate will have a National Board number, sometimes referred to as the “NB Number”, on the plate.

This is not a requirement by the ASME Code, and costs the manufacturer of the autoclave extra money each year to offer this service to their customers.

Tank Fab does this and has done so since we began operations back in 1995. In fact, any autoclave we’ve created is registered with the National Board.

Here’s the link to the National Board’s site where you can request a duplicate of your autoclave’s report.

Non-Destructive Testing, also known as “NDE”, is the term for different types of testing your autoclave goes through during its manufacturing phase.

Radiography, magnetic particle testing, ultrasonic testing, liquid penetrant testing, or hydro-static testing are all options. This testing ensures that your autoclave meets the design and manufacturing requirements of the ASME Code prior to its shipment to you.

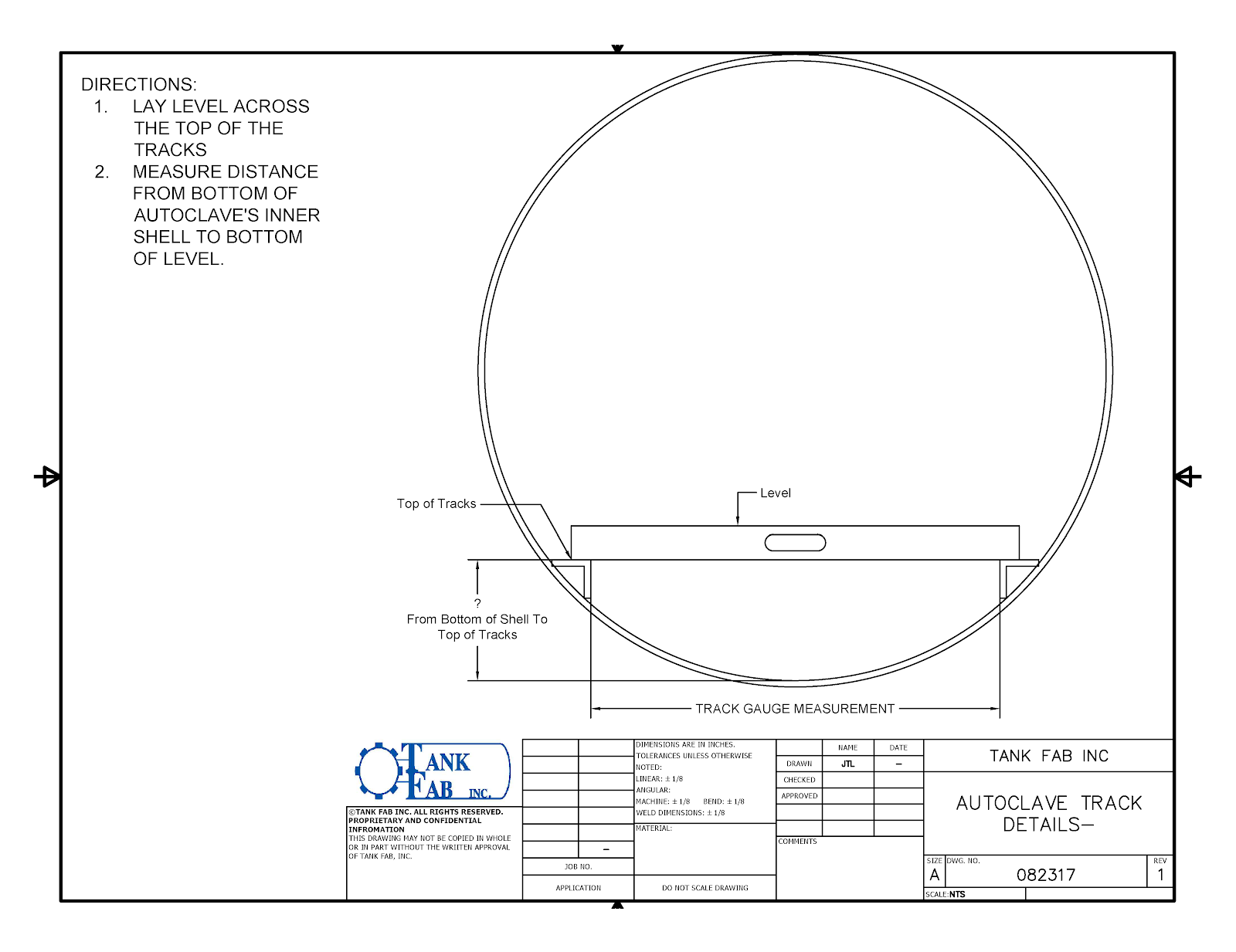

Track gauge refers to the measurement of the distance between the inner edges of the tracks on the inside your autoclave, if so equipped. They say a picture is worth a thousand words so…

Our company’s tagline!

Here’s what it means: When you work with Tank Fab, you’re getting more than just the autoclave. We also provide you with all the piping, valves, pumps, automation, and instrumentation you will need to operate your autoclave and process your product in the autoclave.

Oh… and did we mention we can also provide the material handling system for your autoclave?

Does your autoclave manufacturer do that?

Familiarity with these phrases and what they mean positions you as a go-to source for the autoclave needs within your company.

The people who work with you want to feel confident that you’re qualified to help them meet their production targets and revenue goals.

Autoclave manufacturing terms and definitions are explanations of processes, functions, equipment and other relevant aspects of pressure vessel production.