An autoclave is nothing more than a hollow tube with a door at one end. It becomes a “system” when components are added – like pipes, valves, pumps and boilers – that help it perform a specific job. Learn about the many and varied uses for an autoclave system and how a customized system can benefit your business.

G.I. Joe said it best: “Knowing is half the battle.”

You have to understand the nitty-gritty of your autoclave system to get the most out of it.

Increased production, smooth processes and ultimately, a boost in your revenue are possible with the right knowledge.

Let’s dive into the important details about an autoclave system.

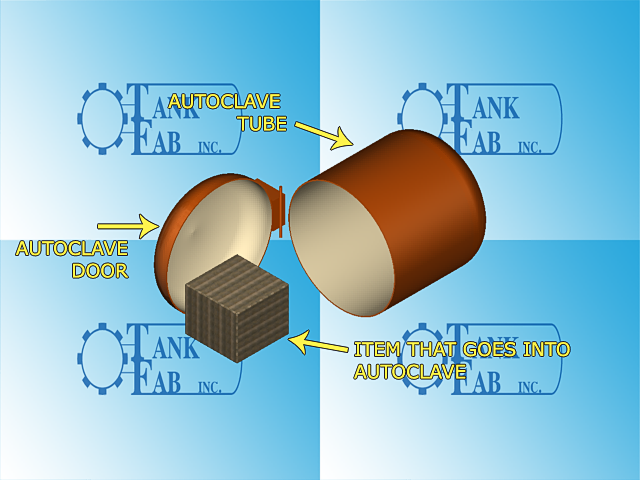

This diagram shows you the basic features of an autoclave.

An autoclave is nothing more than a hollow tube with a door on one end.

There are three basic steps to using an autoclave.

1. Open the door and insert the items to be treated into the autoclave’s tube.

2. Close the door and start the treatment process you’re using for the particular items.

3. When the process is complete, open the door and remove the items you inserted into the autoclave’s tube at the beginning.

The second part of the equation is the “system.”

There are various components that allow the autoclave to actually do the job.

This includes:

Autoclaves perform a multitude of duties.

Next time you go for a dental checkup, ask your dentist about their autoclave, also called a sterilizer.

She’ll have one in her office for sterilizing the shiny items she pokes and prods your mouth with.

Do you ever fly? The fuselage and wings on the airplane were most likely partially manufactured within an autoclave system.

How about the wooden porch or deck you have attached to your home? The wood it’s made of was preserved in an autoclave system.

Do you take a train to or from work? Those wooden ties the train tracks are supported by? You guessed it – they were also partially manufactured in an autoclave system.

What about the tires on your bike? Yep, you guessed it. The rubber was treated in an autoclave system.

That’s really just the tip of the iceberg.

You’re well-versed on the ins and outs of an autoclave system, so now what?

If you want to give your business a boost with smoother processes and the most efficient production, you have to be careful about the autoclave system you purchase.

Determine to buy from a company that listens to and takes the time to understand your unique industry’s needs, that can not only provide you with the autoclave but all the other equipment that makes your autoclave function, and can repair or alter your autoclave system should the need arise.

Is your autoclave system running up to speed? How could you improve your processes?